Transportadores de virutas y sistemas de filtración de refrigerante: automatice la eliminación de virutas e incremente la productividad de mecanizado con soluciones que eliminan los desechos de sus procesos de forma segura.

Los sistemas se crean en función de sus requisitos y pueden personalizarse para gestionar cualquier tipo de viruta y material, desecho, pieza, refrigerante y filtración de refrigerante.

Nuestros diseñadores expertos poseen los conocimientos necesarios para crear una solución adecuada a sus requisitos. Con nuestro largo historial de colaboraciones con marcas internacionales de máquinas-herramienta, es probable que ya lo hayamos diseñado antes, pero también trabajamos con sistemas grandes y complejos de conexión de varias máquinas para plantas de producción totalmente automatizadas.

CARACTERÍSTICAS ESTÁNDAR

- Protección contra sobrecarga/atascos

- Transmisión de velocidad variable (1,1 m/min - 3,3 m/min)

- Colores de pintura - azul / blanco / gris / negro

- Ángulo de inclinación - 60* / 45*

CARACTERÍSTICAS OPCIONALES

- Limitador de par elevado (1,6 m/min, 2,2 m/min, 3,0 m/min)

- VFD o caja de control

- Depósitos de refrigerante

- Filtración de refrigerante (CDF - Filtración por disco de virutas)

- Color de pintura personalizado

- Ángulo de inclinación personalizado

- Toberas personalizadas

- Rieles de acero inoxidable para carga pesada

¿Necesita piezas de repuesto para su transportador?

VISITE NUESTRA PÁGINA DE REPUESTOS

Tipos

Cinta Articulada

Solución transportadora versátil y verificada para diversos materiales, tipos de virutas y cargas de virutas.

Cintas con Paletas Rascadoras

Solución ideal para fragmentos y virutas finos; se mueve marcha atrás recolectando y arrastrando virutas por la rampa hasta el extremo de vertido.

Transportador de virutas de cinta magnética

El transportador de virutas de cinta magnética desempeña una función muy concreta en la gestión de virutas: está destinado a aplicaciones de materiales ferrosos que generan virutas pequeñas y polvillo.

Transportador con barra de empuje

Se emplea en el transporte de grandes volúmenes de todo tipo de fragmentos y se puede montar bajo tierra o en la superficie.

Transportadores de virutas móviles

Sirven para ahorrar tiempo en el vaciado de virutas en máquinas dotadas de transportadores de virutas de tipo tornillo sinfín; permiten la distribución de virutas en receptáculos de mayor envergadura y el vaciado de estas con menor frecuencia.

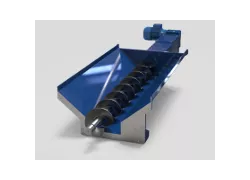

Transportadores de tornillo sinfín

Son ideales para aplicaciones en espacios limitados, virutas pequeñas, diversos tipos de materiales y aplicaciones en seco o en mojado.

Cintas Transportadora

Solución transportadora universal para aplicaciones en las que no intervienen líquidos.

Transportador personalizado

Transportadores con canal de succión que permite que el sistema evacúe polvo y gases durante el mecanizado en seco.

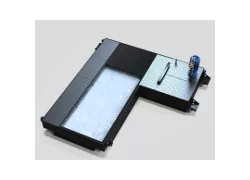

Filtración por disco de virutas (CDF)

El sistema CDF de Hennig, sujeto a patente, emplea un disco pendular micrónico para el filtrado de refrigerante.

Depósitos de refrigerante

Por medio de depósitos integrados o auxiliares, el refrigerante se limpia y recicla con celeridad durante el mecanizado, con lo que se reducen las interrupciones y el tiempo de inactividad.

Sistema de gestión de virutas llave en mano

Le ayudaremos a integrar toda la tecnología y los controles que necesita para automatizar la gestión de virutas y refrigerante.

Redes de transportadores

En el caso de fabricantes de altos volúmenes, los sistemas integrados de Hennig son capaces de automatizar la eliminación de virutas en cualquiera de las máquinas-herramientas de las instalaciones.