Telescopic steel covers provide durable protection of slideways and precision machine components from all types of chips and coolant. Optional components can be integrated to improve durability speed, and access to the machine.

All cover shapes, mounting options, and wiper systems can be customized to meet your requirements. We also repair/replace all brands of way covers.

Online Quote Request Download Quote Request (New) Download Quote Request (Repair) Download Brochure Mounting Instructions & MaintenanceFeatures & Options

Steel / Stainless Steel

Commercial quality steel is used to withstand the abuses of the shop environment. Standard sheet thicknesses range from 1.5 mm (16 gauge) to 3 mm (11 gauge). Other gauges available depending on the application.

Guides

Brass or non-metallic guides can be used on the covers.Small and medium size covers can be supported with non-metallic, low friction guide shoes.

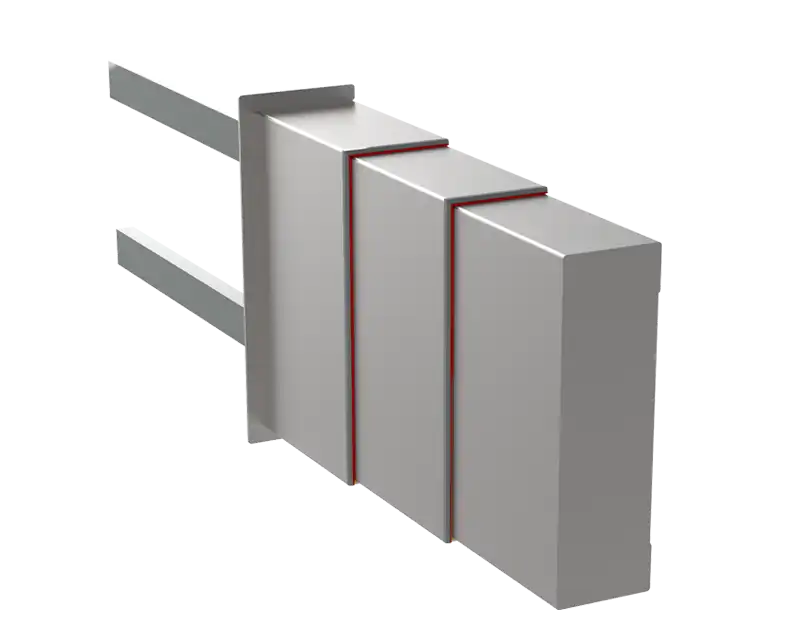

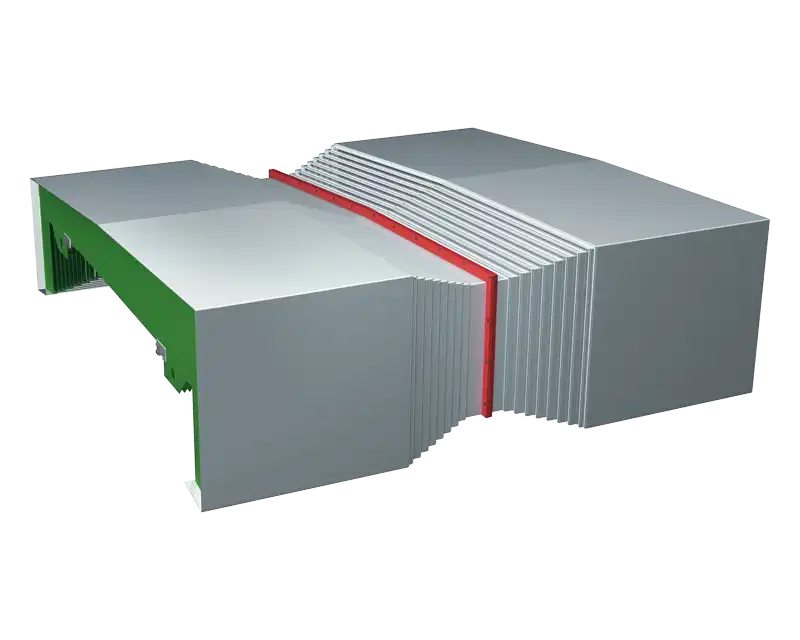

Interlocking Design

Wrap around construction ensures precise location of individual cover sections and automatically provides the necessary initial preload for the flexible wipers.

Wiper Systems

High endurance, insertable polyurethane wipers keep the cover clean and seal out chips, dust and coolants.

Support Rollers

To ensure smooth, accurate operation, large covers can be provided with rollers. Ball bearing, needle bearing, and many other roller options are also available.

Hight Speed Module

Perfect guidance for high speed covers up to 200 m/min (660 ft/min) and accelerations up to 2Gs over the entire traverse path. Ideal for linear motor machines.

Damping Elements (bumpers)

Bumpers are used based on machine speeds.

Wedge Dampener (ME Module)

Used to soften impact on the boxes.

Lifting Lugs

For ease of installation, lifting lugs can be provided.

Way Extension Brackets

Extend from the machine ways to provide support for the cover while it is in a compressed position.

Inspection Openings

For quick, easy inspections hinged or Plexiglas® panes may be specified.

What are telescopic steel covers?

Telescopic steel covers (TSC) are the industry recognized method of protecting guideways and other precision parts of machines from the ingress of chips and sharp-edged waste.

Why telescopic steel covers?

Steel covers are a heavy-duty solution which can protect in the harshest of environments and can also protect against tool or workpiece drops and, in the largest cases, when manufactured robustly enough can even be walked on. They help to increase the service life of equipment and are an essential part of machine tools.

What type of telescopic steel covers do I need?

There are different shapes of our telescopic covers for different areas of application. From simple flat top covers to sloping style to apex roof shaped we can offer the best design solution for your needs. We can reverse engineer your old cover for direct replacements or work from drawings if you have them.

Do you repair telescopic steel covers?

We offer a wide range of services related to telescopic covers—for both Hennig covers and covers from other manufacturers. We repair, service, and replace components of your covers.

Way Cover Shapes & Designs

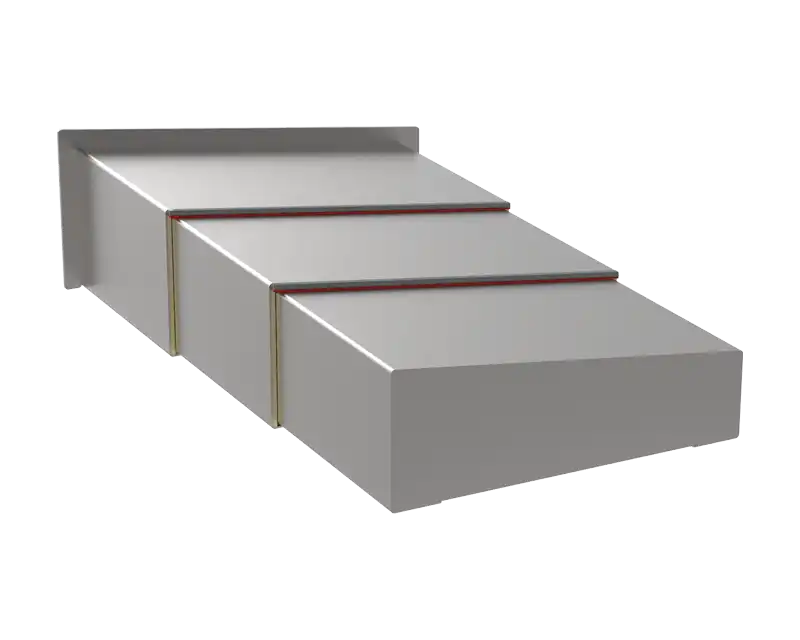

Flat (AA)

The flat, u-shaped design represents the best economical solution for the protection of slideways.

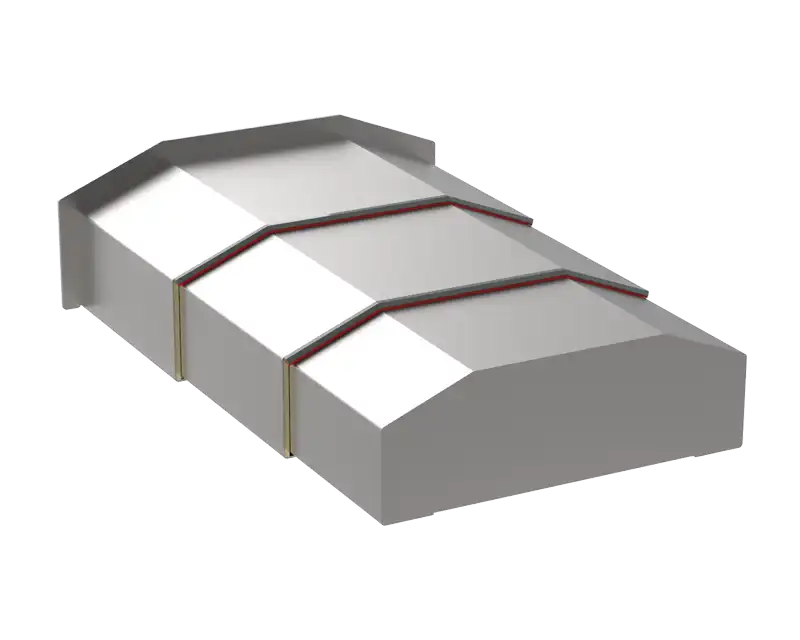

Peak (BB)

The roof-shaped design deflects coolant and swarf and provides higher rigidity and perfect guidance of the boxes.

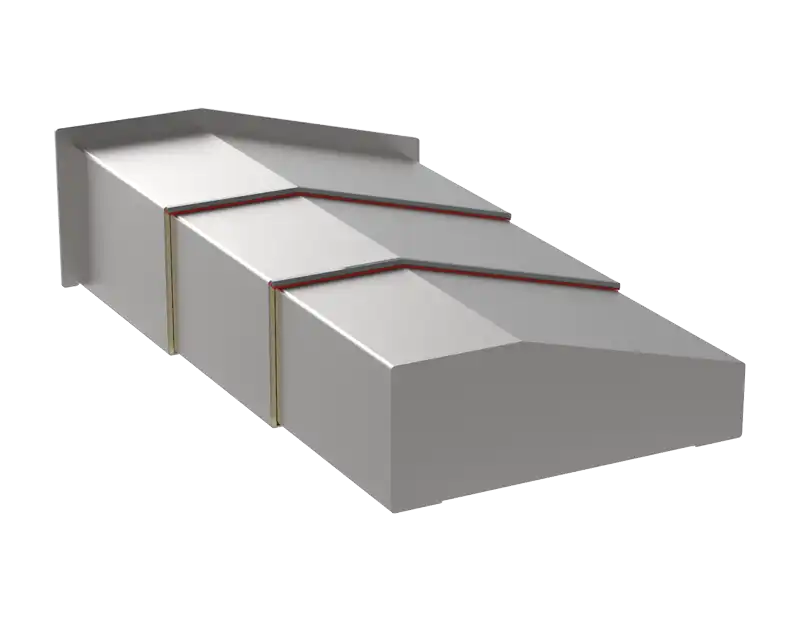

Slant (CC)

The slope of this design ensures the diversion of coolant and swarf in one direction.

Hip Roof (DD)

The flat-roof form is used for broad covers to provide maximum rigidity of the box surfaces.

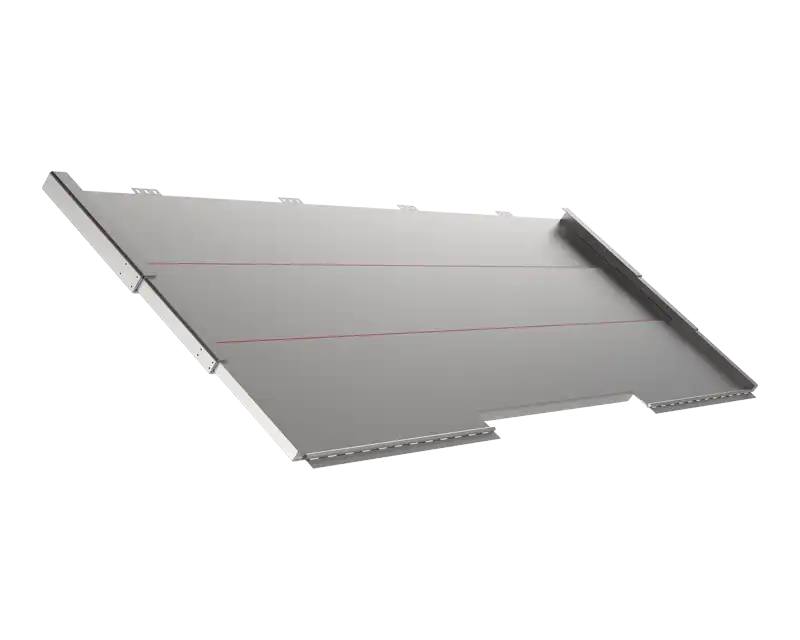

Flat Slope (EE)

This design improves the draining of coolant and swarf and the folded edge increases the boxes rigidity.

Cross Beam

Covers shapes AA, BB, CC, DD, and EE can designed for cross-beam applications.

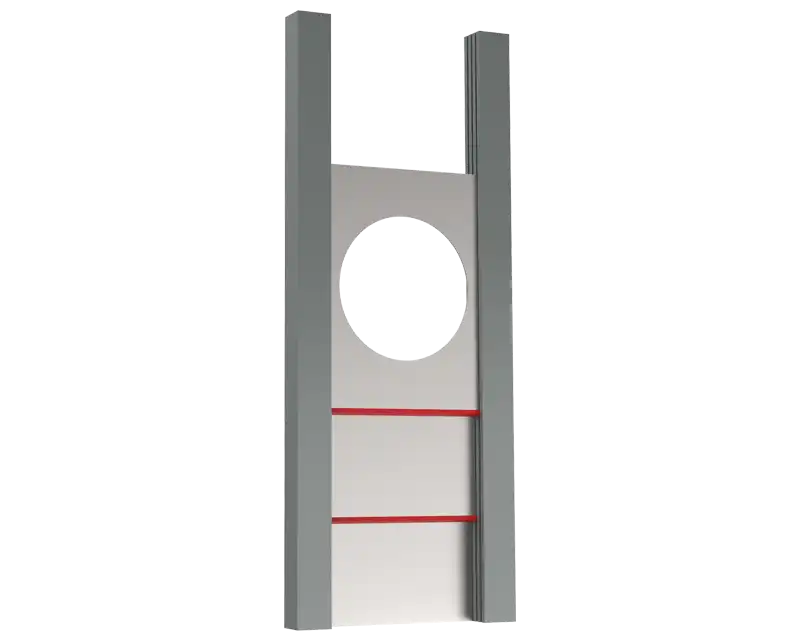

Vertical

In this type of cover, the individual plates slide in separate guide rails. Since these types of covers do not require slideways, they are particularly suited for the protection of column recesses.

Dual Axis

Dual-Axis covers are typically moving behind the tables and under the spindle when space is limited. This design is limited to 3 boxes unless guide rails are used, and must be flat.

Custom Covers

Different requirements and environmental conditions, complicated slideway forms, and less than ideal spacial conditions of special machines demand close cooperation between our design engineers and the machine tool manufacturers.

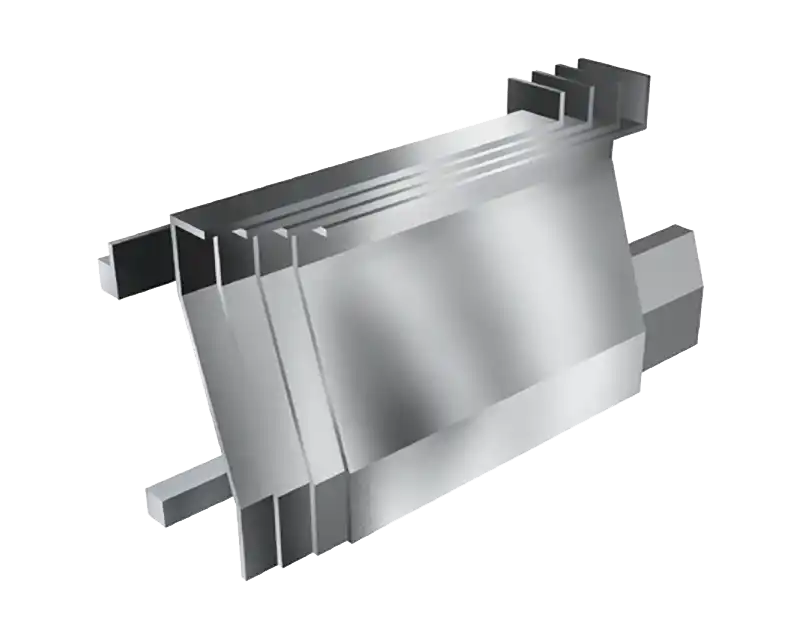

Coupled

By coupling a telescopic steel cover, a longer travel can be obtained. The box height above the ways, based on the same travel, is less with coupled telescopic steel covers than with one individual cover. The compressed length however is longer.

Water Tight

Our standard TSC designs are splash proof and suited for high traversing speeds. For high coolant applications, we offer water-tight covers using gutters to divert coolant.

SERVICE & REPAIR FOR YOUR WAY COVER

We offer service and repair for all way covers (Hennig & non-Hennig brands) with a worldwide network of facilities. Learn more about our worldwide network of service and repair capabilities.

Before Repair