Hennig XY Face Shields

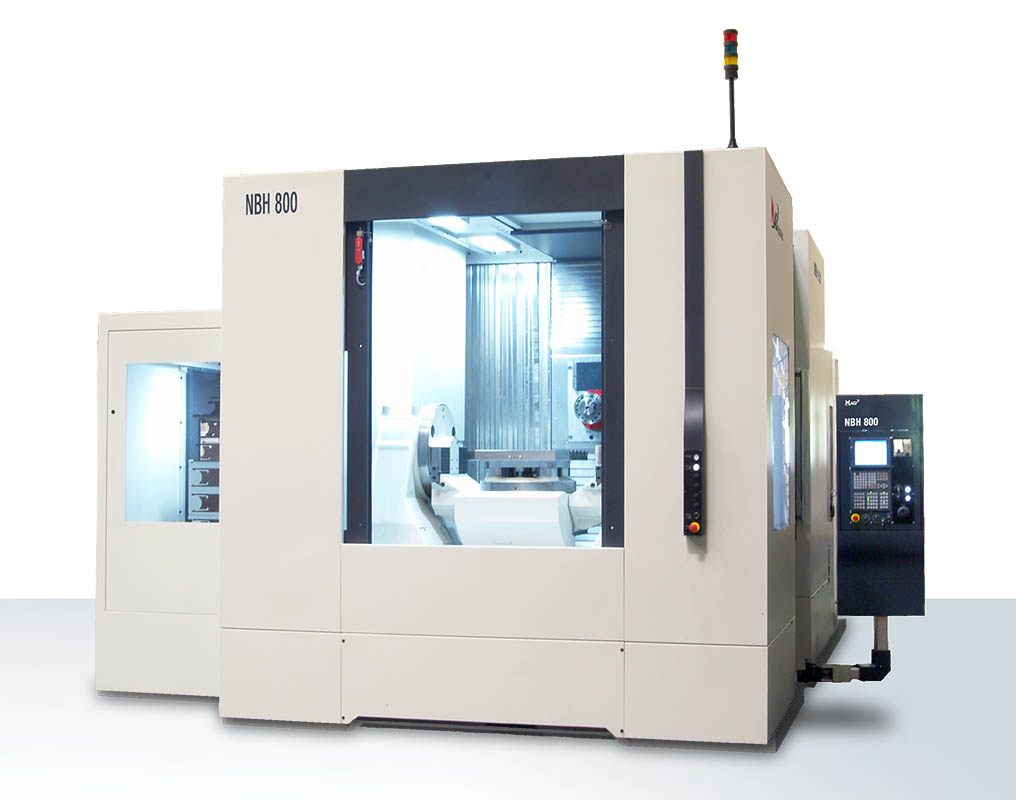

Designed for fast travel and high dynamic loads, face shields are ideal for protection around the machine tool spindle. Our face shields are built to specs based on application, load, aesthetic value and cost.

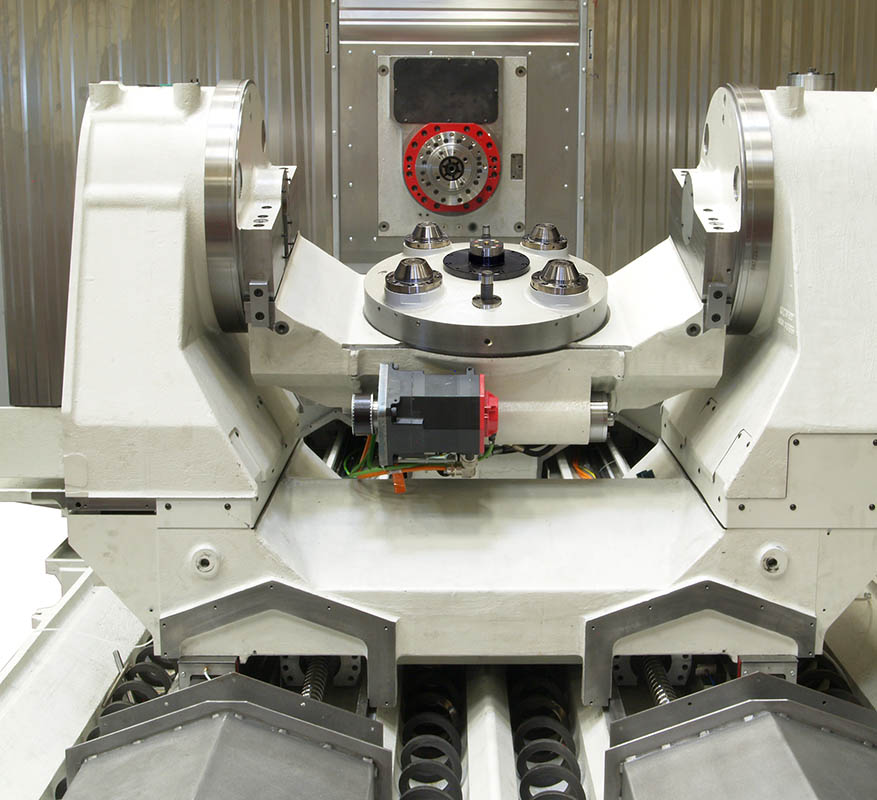

These systems are completely assembled before delivery, and their modular design allows for individual components to be repaired without replacing the entire system.

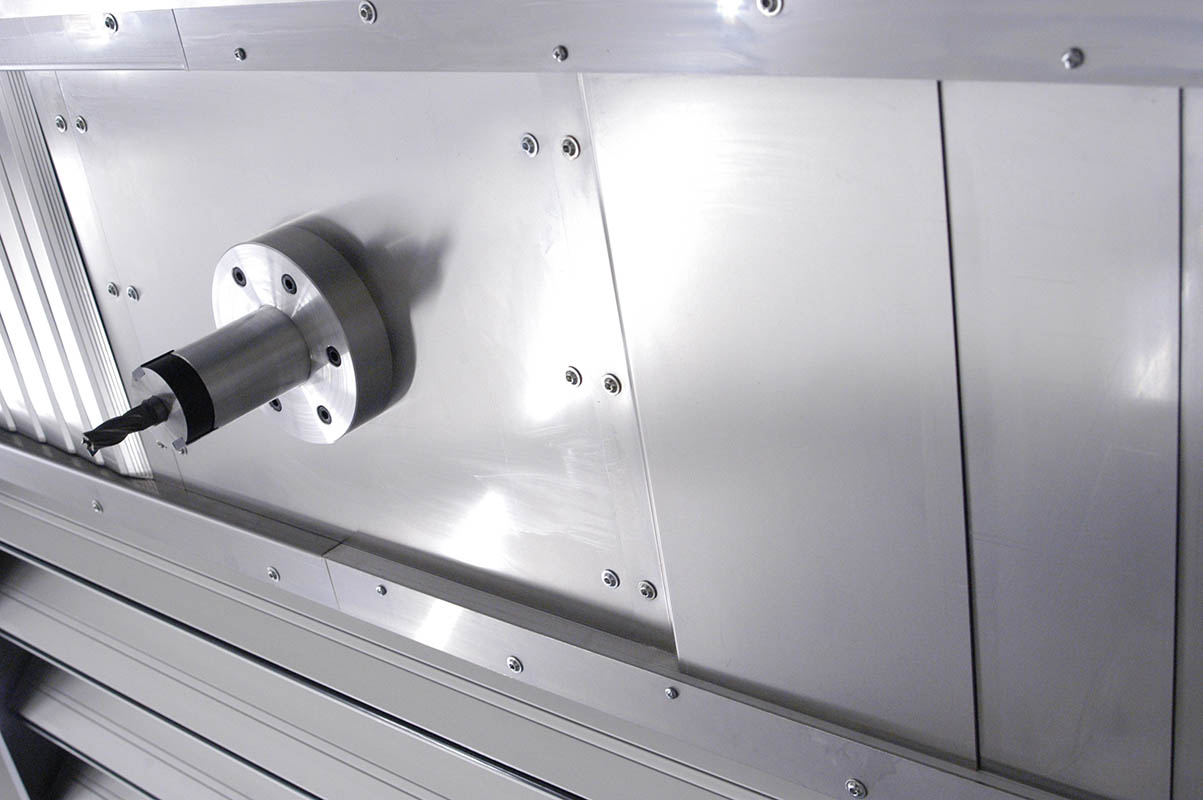

- Ideal for multi-axis slideway and CNC feedback device protection

- Assembly-ready with all necessary parts

- Assembly-friendly, using a compact building block design that allows replacement of individual components

- Resistant to damage from high dynamic forces

- Individually engineered to your specifications and space requirement

- Configured to your specifications, combined with telescopic steel covers, aluminum aprons, lamella bellows, or flex protect covers

GUIDE SYSTEMS

- Mechanical guide system specially designed for aluminum aprons

- The deflector or take-up system, depending on apron type (ALUFLEX or GS20) guides the apron in one or two directions.

- The available space on or inside the machine determines the shape of the apron guide, whether redirection into an available space, or rolled-up spirally, elliptically in any position, including overhead

- The nearly wear free guide system is capable of high speeds up to 100m/min. (3936 inch/min.) and acceleration up to 1g

WHAT ARE XY Face Shields?

XY face shields are a precisely manufactured, multi-axis system. They protect sensitive machine tool components such as motors, electronics, and guides from hot chips and cooling lubricants. The modules, therefore, ensure that the production processes can run without interruption.

WHAT ARE THE ADVANTAGES OF MODULAR SYSTEMS?

Modular systems offer effective protection in tight spaces in production facilities and ensure a long service life and reliability of your machines. In addition, they can be assembled easily and precisely, and individual components can be easily replaced in the event of damage or wear.

HOW DO I FIND THE RIGHT XY MODULES FOR MY MACHINE PROTECTION?

Hennig develops complete, ready-to-install XY face shields that are optimally tailored to your requirements. Talk to us about your challenges and we will design XY face shields that protect your machine while allowing more speed and flexibility.