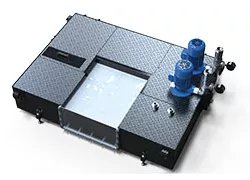

Chip Conveyors, Coolant Tanks & Filtration Designed For Your CNC Machine Tool

- For nearly any machine that makes a chip, we can design a conveyor that fits. We design coolant filtration and coolant recycling systems with any of the pump options or features required to maintain a clean coolant system.

-

The Hennig chip Disc Filtration System can reach nominal filtration down to 25 microns, but we offer further filtration for through spindle, high-pressure systems such as cyclonic, cartridge or paper filtration.

-

If your conveyor system requires integration in the machine controls or automation beyond our standard control system, we can build a tailor-made solution that does the job.

-

If you're looking to further process your chips for shredding or recycling, we can integrate any of the technology required.

-

We have a long history serving the machine tool industry, but we’ve made plenty of specialized conveyors that move finished parts, machined remnants, scrap materials, and other items beyond metal chips.

-

We'll help you integrate all of the technology and controls you need to take chips and coolant management to a higher standard.

Our chip conveyors and disc filtration systems set the standard for removing chips and debris from machine coolant, improving the life of precision machines and the accuracy of output. They are supported worldwide with Hennig’s global sales and support infrastructure, which includes manufacturing facilities and partnerships throughout the industrialized world.

Our worldwide network leads the industry in developing innovative chip conveyor technologies, offering a complete range of chip conveyor solutions tailored to particular machine types, performance requirements, and work area considerations. Our chip conveyors outperform expectations, even in the most demanding production environments, and they do it more efficiently and with less maintenance than other conveyor solutions.

CHIP CONVEYOR FAQS

WHY ARE CHIP CONVEYORS NEEDED?

Chip conveyors are required in machining production to remove chips from the work area of a CNC machine and can be processed for recycling.

HOW DOES A CHIP CONVEYOR WORK?

Chip conveyors are used to remove chips from machine tools and put them into a collection container while also separating the chips from the coolant. Chips are removed from the machine, so it does not become jammed with chips over time.

WHAT TYPES OF CHIP CONVEYORS ARE THERE?

Depending on the material and the type of chip produced, there are different types of chip conveyors with different technology: hinge belt conveyors, scraper belt conveyors, magnetic conveyors, medium filtration conveyors (Pure Flow), high-end filtration (CDF, or chip-disc filtration), and auger conveyors to name a few. To view all of Hennig’s conveyor types, visit https://hennigworldwide.com/conveyors-and-filtration/.

WHAT ARE THE ADVANTAGES OF A CHIP CONVEYOR?

Chip conveyors present a number of advantages for companies, including in increase in labor productivity, minimizing risk of accidents, and recycling of clean coolant after filtration.

COOLANT FAQS

WHY DOES COOLANT NEED TO BE CLEANED?

Coolant is contaminated by processing residues such as chips, dust, etc. and shortens the life of pumps and valves within coolant systems. This also improves your tool life and the quality of the parts being produced. In order to filter coolant from these impurities, filtration systems are used for coolant processing.

WHAT METHODS ARE THERE FOR CLEANING COOLANT?

Various methods are available for cleaning coolants, including cartridge filtration, bag filters, cyclonic filters, paper filtration belts, and magnetic filtration. Learn more about coolant filtration here: https://hennigworldwide.com/coolant-filtration.

WHAT IS COOLANT AND WHAT IS IT USED FOR?

Coolants can be water-based, synthetic, or oil-based. Coolant is used in industrial production with CNC machine tools. They cool and lubricate the workpiece to be machined and thus enable economical operation.

HOW DOES THE COOLANT FILTER WORK IN THE CDF PROCESS?

In the CDF (Chip-Disc Filtration) process, the contaminated coolant passes through a stainless-steel medium that removes the particles and allows only the clean coolant to pass through. This can filter down to 25-30 microns of nominal filtration. The use of the above-mentioned products can filter down through spindle-type work.