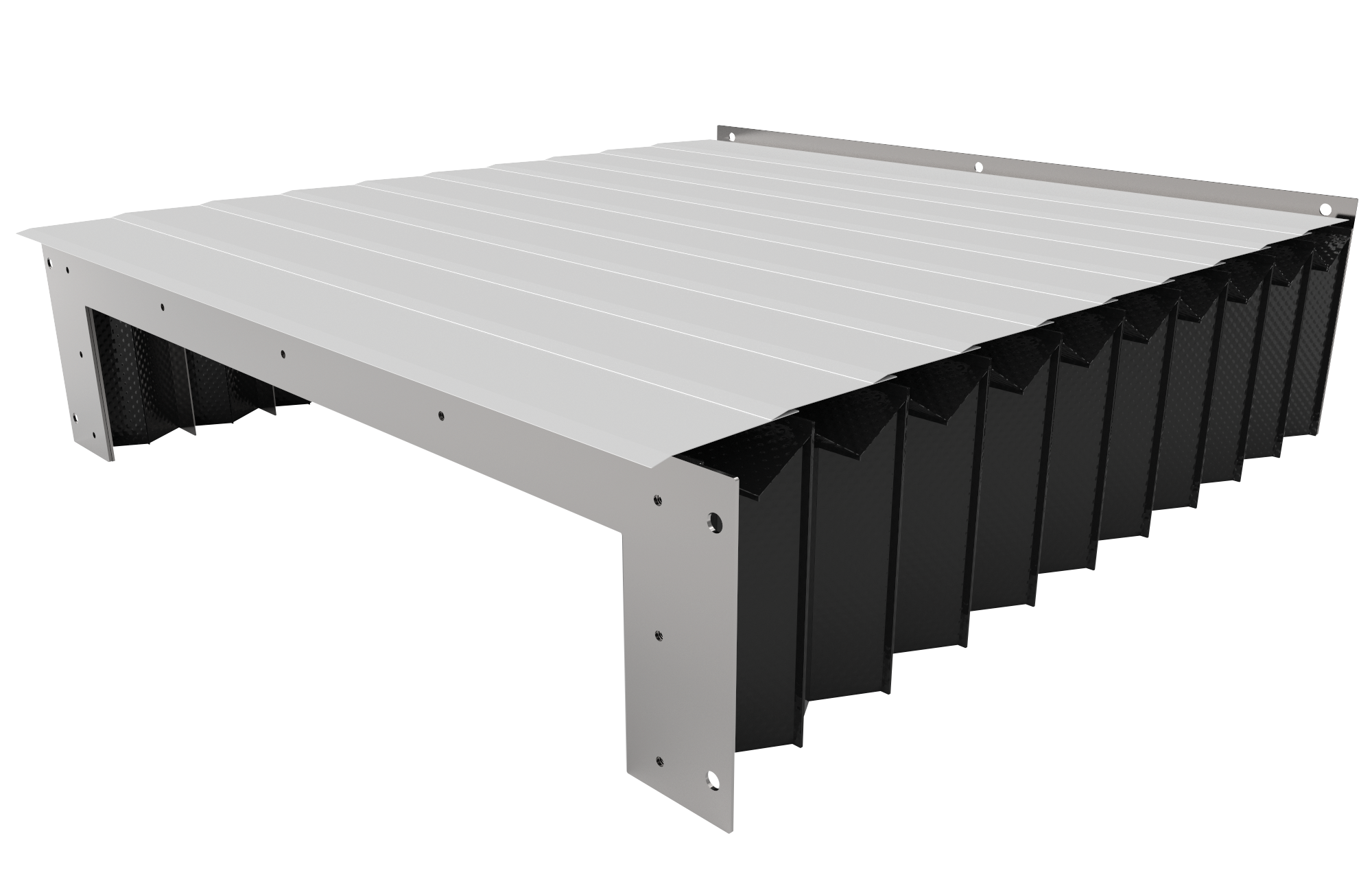

Fixed bellows fill the gap between telescopic steel covers and conventional bellows. Stainless Steel cladding protects the bellows against red-hot debris, sharp-edged swarf, or mechanical strain. Each fold has its own guide frame which is attached to the cover material.

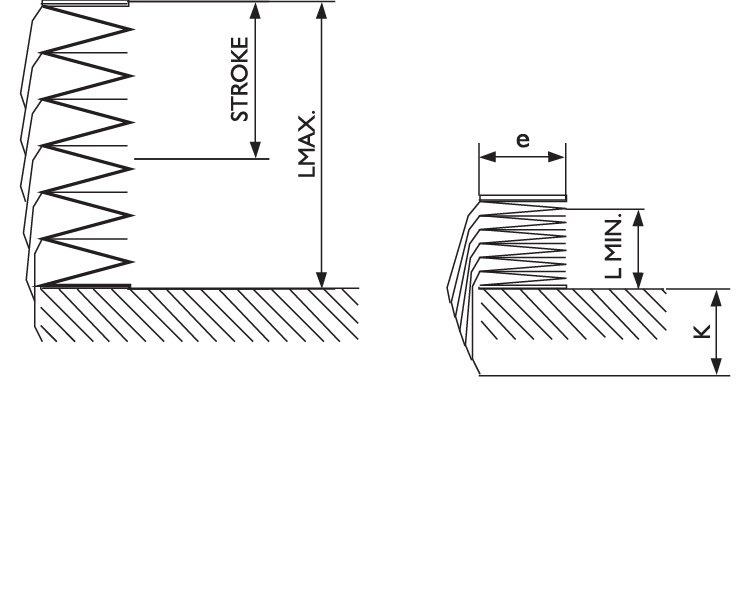

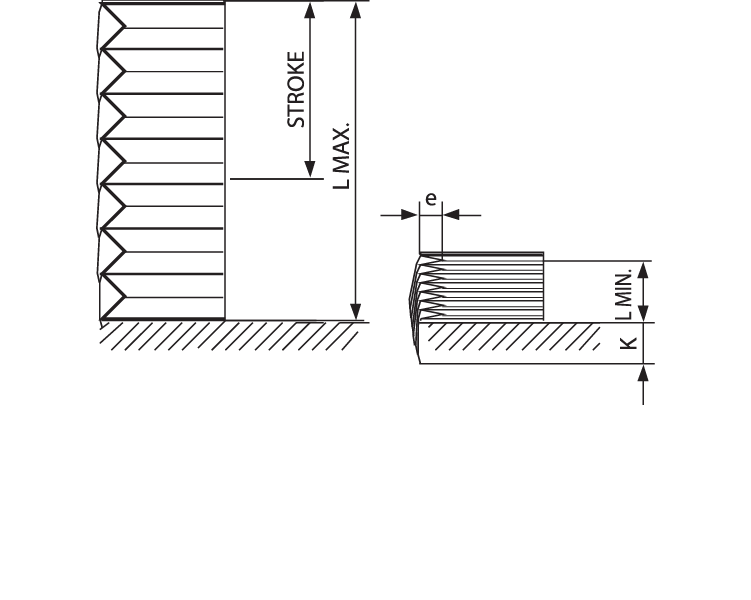

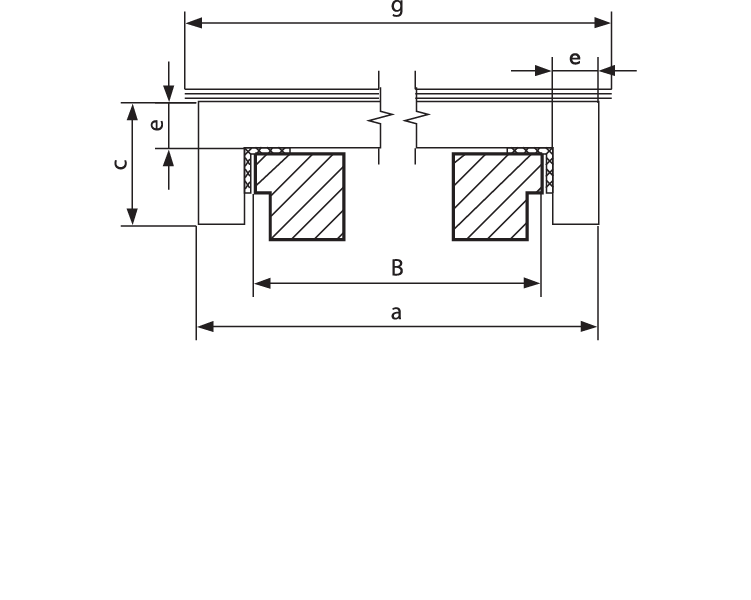

Dimensions

| Fold Height (e) | Extensions per Fold FLAT (AZ) | Extensions per Fold FOLDED (AZ) | Width of Lamellas (K) |

|---|---|---|---|

| 24 | 27 | 33 | 61 |

| 30 | 39 | 45 | 76 |

| 35 | 49 | 55 | 81 |

| 40 | 59 | 65 | 91 |

| 45 | 69 | 75 | 101 |

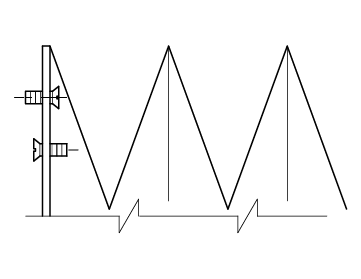

Flat Bellow

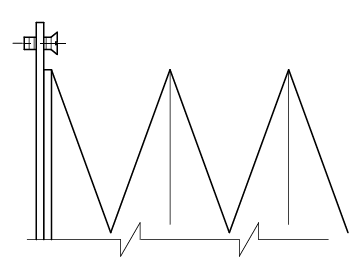

Folded Bellow

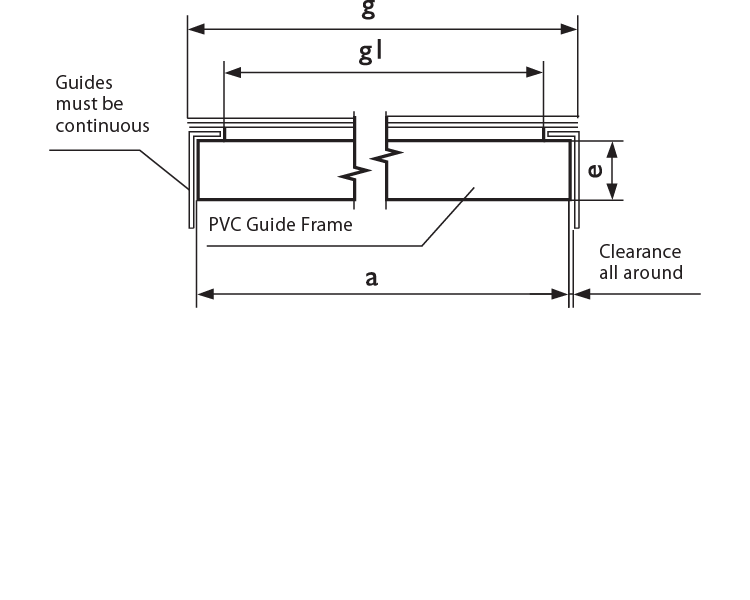

Mounting Options

Full Fold

External Flange

Material Options

| Carrier | Coating (Ext/Int) | Specification # | Thickness (mm) | Types | Wear Resistance | Oil / Grease / Collant Resistance | Swarf / Weld Splatter / Forging Scale Resistance | Flame Resistance | Self Extinguishing | Surface Stability | Extension / Compressions Ratio | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Heat Sealed | Stitched | Steel Clad | Round Stitched | |||||||||||

| Polyester | PUR / PUR | OZ-PUR | 0.35 | x | x | x | + | + | + | - | o | ++ | + | |

| Polyester | PUR / PUR | ERA 7810 | 0.22 | x | x | + | o | o | - | o | o | ++ | ||

| Kevlar | PUR / PUR | PUR-KEVLAR | 0.36 | x | x | x | x | ++ | + | + | + | + | ++ | + |

| Polyester | PVC / PVC | OZ-23 | 0.23 | x | x | + | - | - | - | - | o | ++ | ||

| Polyester | PVC / PVC | OZ-35 | 0.36 | x | x | x | + | + | o | - | o | + | + | |

| Nomex | ALU / - | ALUM-ARAMID | 0.35 | x | x | x | + | o | ++ | + | ++ | + | + | |

| Polyester | PTFE / PUR | PUR / TEFLON | 0.3 | x | x | x | ++ | ++ | o | - | o | ++ | + | |

| Nylon | NEP / NEP | NEOPRENE | 0.4 | x | x | x | x | ++ | ++ | ++ | - | o | ++ | o |

| Nylon | HYP / HYP | HYPALON | 0.4 | x | x | x | x | + | ++ | o | - | o | + | o |

| Commonly Used Materials | Details |

|---|---|

| Polyurethane (PUR) | Temperature Resistance up to 120° C |

| Polyurethane (PUR) Aluminized | Temperature Resistance up to 400° C (stitched type only) |

| Nomex | Flame Resistance. Ideal for laser machines |

| Kevlar | High Strength. Abrasion and puncture resistant. |

| Polyvinylchloride (PVC) | Self Extinguishing |

| Teflon Polytetraflourethylen (PTFE) | Anti-adhesive. High chemical and thermal resilience. Corrosion proof. Dirt & water repelling. |