Vertically mounted bellows with no overhang. Hinged bellows are the perfect solution for protection of the Z-axis from hot / sharp chips, weld splatter, and any other debris from the machining environment. Each steel plate is flexibly attached to the PVC frame allowing the plates to lie flat on the bottom of the machine enclosure.

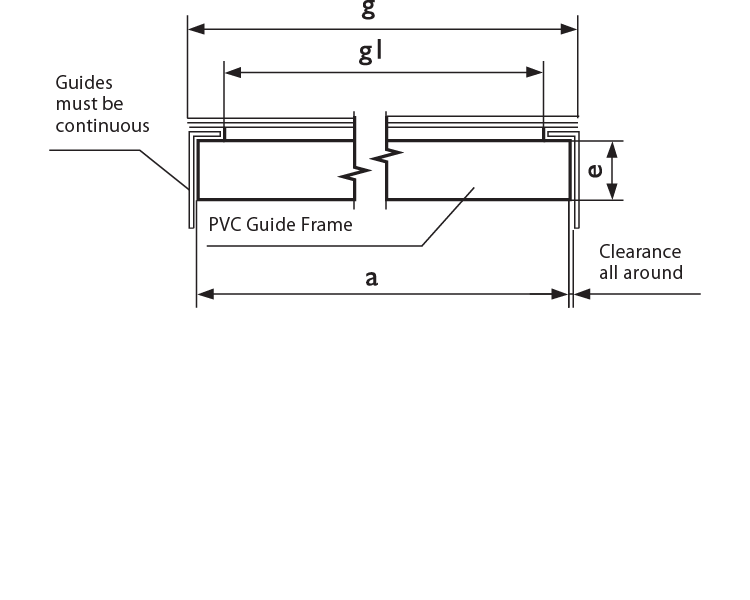

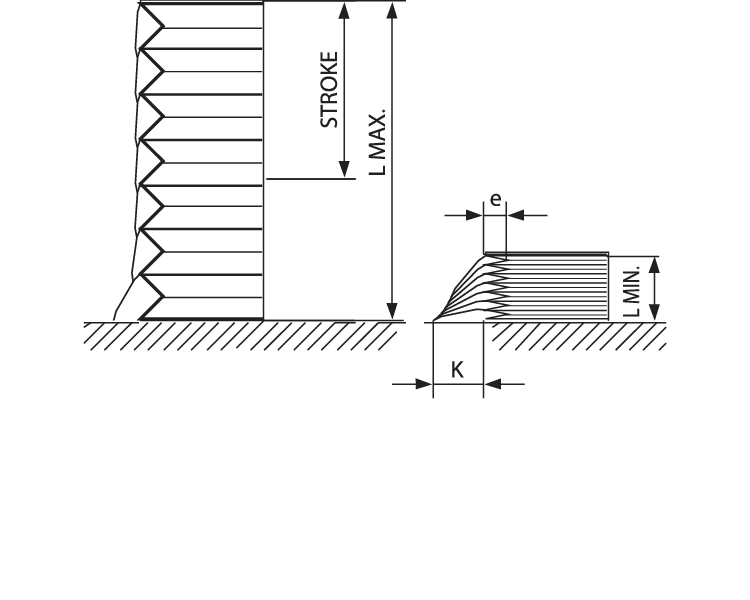

Dimensions

| Fold Height (e) | Extensions per Fold FLAT (AZ) | Extensions per Fold FOLDED (AZ) | Width of Lamellas (K) |

|---|---|---|---|

| 24 | 30 | 36 | 67 |

| 30 | 42 | 48 | 82 |

| 35 | 52 | 58 | 87 |

| 40 | 62 | 68 | 97 |

| 45 | 72 | 72 | 107 |

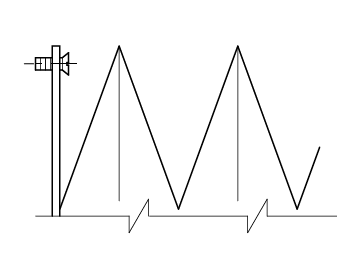

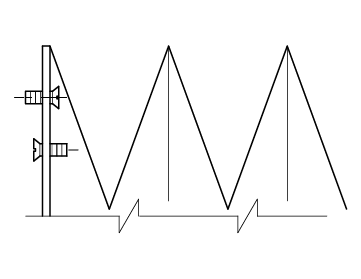

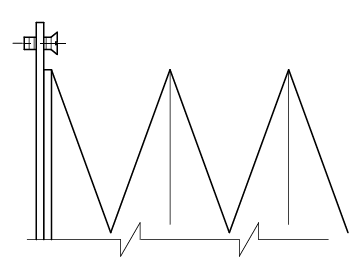

Flat Bellow

Folded Bellow

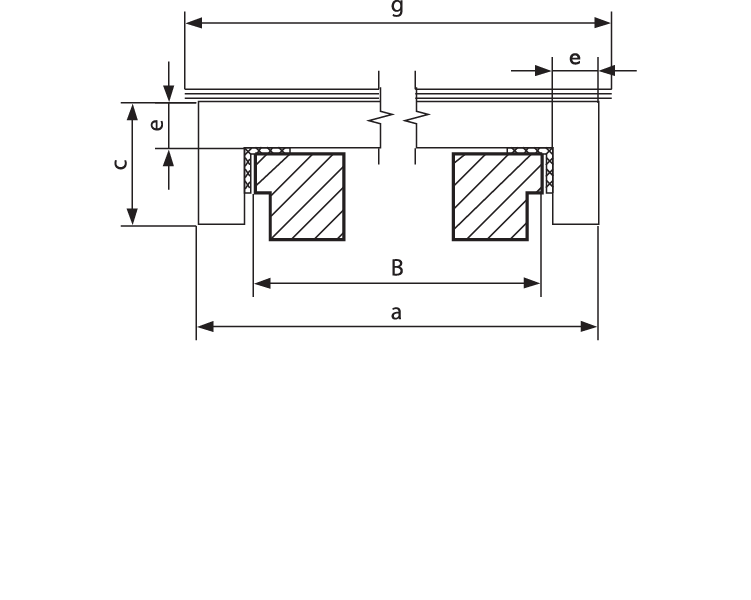

Mounting Options

Half Fold

Full Fold

External Flange

Material Options For Hinged Steel Lamella Bellows

Material is selected based on the application / operating conditions.

Decisive factors are: mechanical / thermal strain and type of chips / liquids

| Carrier | Coating (Ext/Int) | Specification # | Thickness (mm) | Types | Wear Resistance | Oil / Grease / Collant Resistance | Swarf / Weld Splatter / Forging Scale Resistance | Flame Resistance | Self Extinguishing | Surface Stability | Extension / Compressions Ratio | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Heat Sealed | Stitched | Steel Clad | Round Stitched | |||||||||||

| Polyester | PUR / PUR | OZ-PUR | 0.35 | x | x | x | + | + | + | - | o | ++ | + | |

| Polyester | PUR / PUR | ERA 7810 | 0.22 | x | x | + | o | o | - | o | o | ++ | ||

| Kevlar | PUR / PUR | PUR-KEVLAR | 0.36 | x | x | x | x | ++ | + | + | + | + | ++ | + |

| Polyester | PVC / PVC | OZ-23 | 0.23 | x | x | + | - | - | - | - | o | ++ | ||

| Polyester | PVC / PVC | OZ-35 | 0.36 | x | x | x | + | + | o | - | o | + | + | |

| Nomex | ALU / - | ALUM-ARAMID | 0.35 | x | x | x | + | o | ++ | + | ++ | + | + | |

| Polyester | PTFE / PUR | PUR / TEFLON | 0.3 | x | x | x | ++ | ++ | o | - | o | ++ | + | |

| Nylon | NEP / NEP | NEOPRENE | 0.4 | x | x | x | x | ++ | ++ | ++ | - | o | ++ | o |

| Nylon | HYP / HYP | HYPALON | 0.4 | x | x | x | x | + | ++ | o | - | o | + | o |

++ Excellent + Good o Suited Under Certain Conditions - Unsuitable

| Commonly Used Materials | Details |

|---|---|

| Polyurethane (PUR) | Temperature Resistance up to 120° C |

| Polyurethane (PUR) Aluminized | Temperature Resistance up to 400° C (stitched type only) |

| Nomex | Flame Resistance. Ideal for laser machines |

| Kevlar | High Strength. Abrasion and puncture resistant. |

| Polyvinylchloride (PVC) | Self Extinguishing |

| Teflon Polytetraflourethylen (PTFE) | Anti-adhesive. High chemical and thermal resilience. Corrosion proof. Dirt & water repelling. |